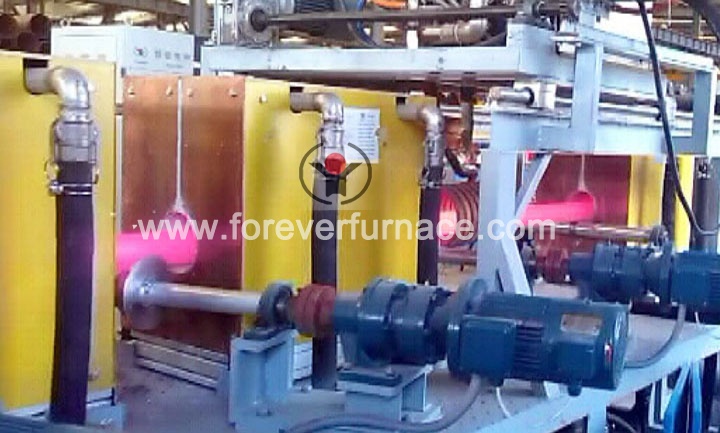

Long bar heat treatment line

Features:

● Application: Heat treatment line for long bar, long shaft, long round bar

● Size : ø 10-150mm

● Material: S45C, SCM440,42CRMO4, 16MNCR5, 40CR4

Product Detail

Application Video

Product Tags

Technical Parameter for Long bar heat treatment line

● Steel grade:S45C, SCM440,42CRMO4, 16MNCR5, 40CR4

● Bar size :Ø20~Ø60mm

● Bar length : 7000mm

● Productivity:Ø20~Ø25 800~850 kg/h

Ø25~Ø30 850~900 kg/h

Ø35~Ø45 950-1000 kg/h

Ø45~Ø60 1000-1100 kg/h

Compared with the other supplier’s long bar heat treatment line, Forever advantages:

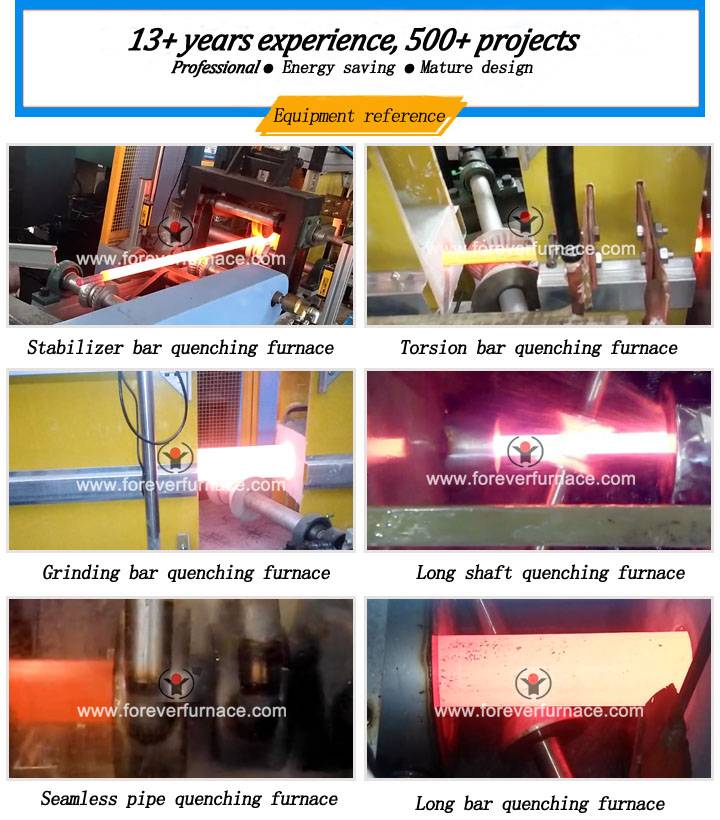

● Rich experience

Our company has dedicated in designing and manufacturing steel bar quenching and tempering for ten years. So far, we have manufactured almost 100 sets of bar quenching and tempering line. We have deep understanding for different material slight difference. The process is mature and stable, running is reliable.

● “One key” operation

At present, most manufacturers in China manually adjust and test the parameters of different sizes of steel bars quenching and tempering. However, our technicians have already set up corresponding heat treatment parameters for different specifications of the steel bars for users, only need one worker to operate. The operator only needs to choose different steel bar process No. in the console HMI, the system will run as per the setting parameters. So the operator for this system only need simple training, no need special professional skills. And Programmed operation ensures consistency and stability of product quality compared with manual adjustment.

In the operation of the equipment, there is a complete data monitoring, process records, traceability is strong. The man-machine interface of the console will display production data, such as temperature, current, voltage, water pressure, etc.. The data can be stored in the system for a period of time, which is easier for users to check in future. Users can also download production data to the U disk for long-term storage.

● As the steel bar has many sizes, the user need to replace different induction heaters to meet production requirement. Our intelligent intermediate frequency power supply doesn’t need any parameter adjustment, which makes user’s operation easier.

● After our equipment arrived in user’s plant, we will send technician to install and debug the equipment. After our technician finish parameter setting and return to our plant. In future, if the user need to add other size bars process parameters, we can send recipe parameters to customers by internet. User can input the console.

As the professional manufacturer of induction heating system, Forever is ready to give you the most suitable induction heat treatment solutions as per your specific requirement.

Contact person: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)